PRECISION CUTTING

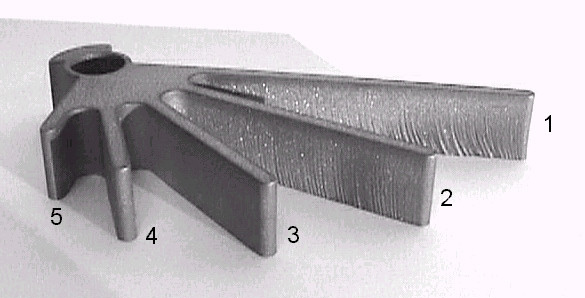

With waterjet cutting, the quality of the edge of a cut part can vary in accuracy. The quality of the edge ranges from Quality 1 to Quality 5 (Q1 - Q5), with Q5 being the most accurate edge quality. Below are details about the edge quality options that are available when using OMAX waterjet machines:

Quality 1 – Rough cut

A Q1 is a rough cut, often described as a "separation cut". The edge has pronounced striations / lines. Whilst not a quality edge, a Q1 is ideal for testing cuts due to very high cutting speeds.

Quality 2 – Medium cut (Similar finish to laser)

The striations are less noticeable than in a Q1 cut, and this is described as a medium rough cut. Cutting speed is a little slower than a Q1 cut.

Quality 3 – Good finish ( most common )

This is the standard machining cut and most commonly used edge quality.

Quality 4 – Very Good

With minimal striations, the Q4 edge quality delivers a high quality finish.

Quality 5 – Satin Finish (the best finish)

No striations and a very high quality, precise finish. The most accurate edge quality.

In abrasive waterjet machining, the cutting speed and the edge quality are directly related to each other. The higher the quality, the slower the cutting speed.

As the time taken to cut parts with an abrasive waterjet is usually a major factor in the cost of project, you must take into consideration the requirements in the job specification and select the appropriate edge quality to give you the edge quality you need at the fastest possible cutting speed.